Owners and project teams have numerous potential motivations to use climate smart wood in construction. These include but are not limited to: project ESG goals, improved tenant environment, and pro forma cost benefit among others.

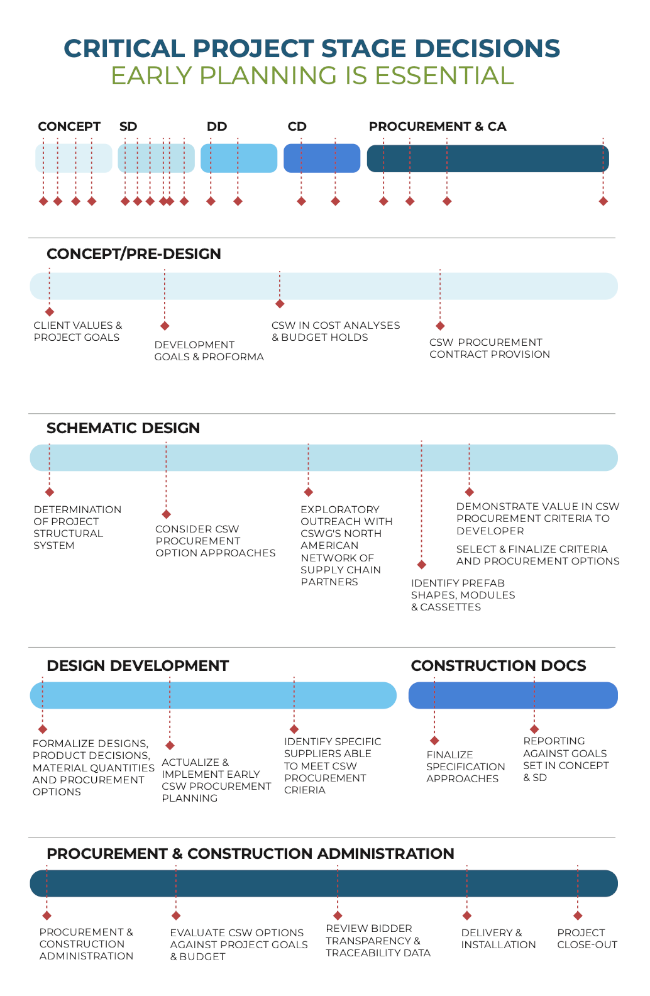

Projects considering mass timber as a structural system typically make a commitment to proceed at three different stages.

There may be inherent tensions within traditional delivery methods (ie, SD, DD, CD, CA) where the final specification for timber elements are not released until sometime in the CD phase or even end of CD phase. If the scope is bid from the final CD spec and drawings without earlier work to explore specification options with prospective CSW vendors, opportunities to secure the best set of outcomes may be lost.

As a general rule, Design-Build delivery offers more opportunity for early and regular collaboration on procurement priorities.

Finally, there are many more opportunities to incorporate CSW procurement in a project beyond the structural system or other mass timber components. Oftentimes nonstructural wood elements of a design are easier to source creatively since they are not as beholden to structural or code performance parameters. Do not overlook CSW sourcing opportunities for interiors or envelope systems as these can arguably serve as an even more engaging touchpoint than structural systems for owners and their tenants.

©2024 Climate Smart Wood Group. All rights reserved. Privacy Policy